Whenever it is feasible to utilize robots in the factory, manufacturers will often find that option irresistible. It is universally agreed that robotics technology has enabled significant productivity boost in manufacturing, especially in a large, monotonous, and autonomous assembly line (e.g. automotive plant).

What is interesting: if you ask the same manufacturers to use the same robots side-by-side with their personnel, suddenly everybody turns skeptical and asking if they are exposing their personnel to hazards. That is normal, because while everybody wants spend less effort at work, which robots could easily provide, nobody wants to get hurt.

Robots that are intended to work alongside, interact, or assist human in their work are commonly known as ‘collaborative robot’ (or ‘cobot’ in short). Considering its application, it is vital to consider safety to ensure overall safety of cobots and ensuring compliance with regulatory matters. There are a few types of cobots, but the most popular type of cobot today is Power and Force Limited (PFL) robot, and it will be a good start to understanding cobots.

The Safety Standards for Cobot

One of the most important standard for collaborative robots is the ISO/TS 15066, which was established over a six-year period by representatives of 24 countries to address the safety of collaborative robot applications. The standard addresses the limit criteria on mechanical loading for both transient and quasi-static contact, and risk assessment should be according to EN/ISO 12100.

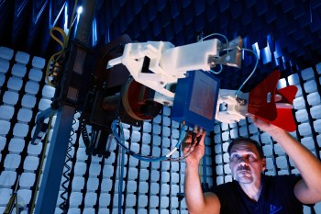

Constructional and Workspace Evaluation

In ensuring robotics safety, it is crucial to include the safety considerations during its construction evaluation. The considerations may include: electrical, fire and shock hazards; mechanical safety and endurance; moving parts; pressure; batteries; safety devices; and abnormal conditions. Some standards such as EN 60204-1, UL 1740, and NFPA 79 provide good reference.

To ensure that the cobot will be fit-for-use in different work environment, it must be tested to various factors. Some factors that should be considered in the cobots functionality are: temperature, altitude, humidity, and electromagnetic compatibility (EMC).

Functional Safety

Whether the robot system relies on approved off-the-shelf parts or custom technology, a functional safety evaluation must be performed. Terms such as “safety rated”, “fail safe” or “functional safety analysis” are applied to a control system meant to protect employees or other cobot operators. These control systems can include safety rated stop and protective stops, slow speed functions, limited force functions, person detection, and others.

Cybersecurity

Technological advances including sensors, smart technologies, and cameras facilitate cobot connectivity to the Industrial Internet of Things (IIoT), enterprise resource planning (ERP) systems, and warehouse management systems. Networked control systems are used to monitor and manage efficiency, automation, and maintenance of cobots. This connectivity (often through corporate network or even the internet) poses a cybersecurity concern.

Other useful information..