The electronic safety case concept has been around for a long time but has struggled to gain widespread traction, perhaps because of its perceived complexity and the implied need for bespoke software.

Today, however, e-safety cases can be produced using simple software found on most computers, in ways that make safety information more accessible and engaging.

What Is an E-Safety Case?

The idea behind an e-safety case is to provide a simple, intuitive and more user-friendly tool than a traditional, often impenetrable, and lengthy paper-based safety case, which might depend on hundreds of supporting references.

Its purpose and the information presented remains the same as a traditional safety case - i.e. to describe the case for safety, for example, by identifying the most significant hazards and the controls available to ensure risks are acceptably low, including safety critical equipment and human actions.

The key difference, though, is that an e-safety case is interactive, using clickable links as a means of connecting and navigating to related information.

How to Develop Your Own E-Safety Case

In developing an e-safety case, the first question to be answered is, "Who are the users?" Defining this from the start will determine what information is included, at what level, and how that information is accessed.

For example, if the purpose of producing the e-safety case is for submission to the regulator then the presentation will necessarily focus on key hazards, leading the reader through the arguments that risk levels are as low as reasonably practicable (ALARP); whereas operators may be more interested in understanding the safety critical context of their day-to-day roles.

The level of sophistication and interactivity can be tailored to suit the organisation and intended use. This can range from including simple hyperlinks within a single PDF document, to creating a web-based portal providing content and access to all supporting components of the safety case, from safety assessment to engineering substantiation to operating procedures and maintenance requirements.

There may also be useful links to the live output from ongoing safety management processes, such as safety performance indicators, audit findings and defect reports.

Why Should You Develop E-Safety Cases?

The main advantage of an e-safety case over a traditional safety case is the ease of accessibility to relevant information from multiple entry points, often making use of graphic navigational aids.

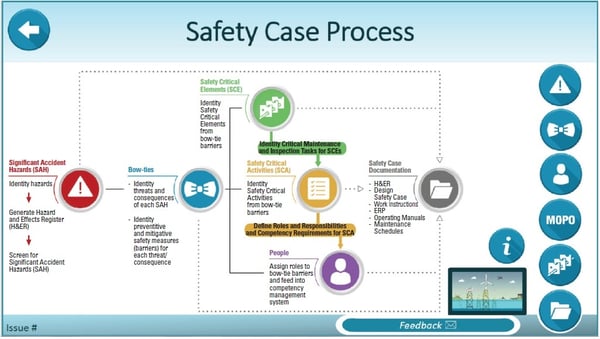

In the example of a homepage shown in Figure 1, the user can navigate to view major hazards, bowties, safety-critical controls, or job roles. On a separate web page describing the safety case process, shown in Figure 2, the user can navigate to the same places. The power of modern search engines can also be brought to bear, allowing specific information to be tracked down in seconds.

Figure 1 - E-safety case homepage for an offshore wind farm

Figure 2 - Safety case process

Looking outwards, an e-safety case can be hyperlinked to related documentation such as procedures, method statements, alarm catalogues, job descriptions, risk assessments, etc., thus providing comprehensive and speedy access to the management system. This has the added benefit of highlighting the 'line of sight' from a hazard to its barriers and on to the actual operating controls.

With such a tool in place, users at all levels of an organisation can quickly gain an appreciation of the main hazards, as well as seeing how their role contributes to assuring safety, with many of the key resources needed to do their job at their fingertips. Moreover, this kind of utility naturally lends itself to supporting job induction or awareness training.

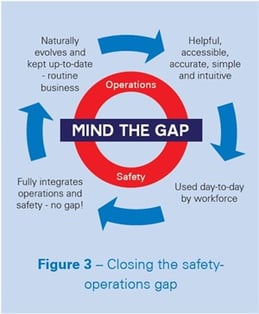

Perhaps the greatest benefit of an e-safety case is that it can become a live basis for safety. It can evolve naturally, hand-in-hand with the facility, eliminating the gap between operations and safety (see Figure 3).

Challenges to Using E-Safety Cases

One reason for not developing an e-safety case is the often-daunting prospect of establishing, maintaining and updating such an interlinked set of documents. However, if one accepts the goal of keeping a safety case live, this endeavour should be no more taxing than the paper-based equivalent. In fact, the linked nature of the e-safety case can be used to help identify the potential knock-on effects of change.

Robust processes are needed to control and approve revisions (which may be suggested by users online), albeit sufficiently streamlined to prevent bottlenecks. For simple e-safety cases, these quality processes may be similar to their paper counterparts; whereas for more sophisticated systems, electronic work flow may be employed.

A common pitfall is to allow the e-safety case to grow into a solution to all things, given its potential functionality. Not only can the intended focus on safety be lost, but the initiative (as with any overambitious software project) is more likely to fail.

A good e-safety case should not lose sight of its primary objective – to improve understanding, accessibility, and relevance.

A Steep but Rewarding Learning Curve

In today's world where answers to most questions can be Googled instantaneously, isn't it time the safety world caught up? The development of e-safety cases is no more onerous than conventional safety cases, it's just different. Climbing the learning curve is a small price to pay for the benefits: user-friendly, live safety cases, accessible to all, promoting faster and deeper understanding of the risks to safety.

Taking things further, the e-safety case can be blended with technological innovations such as virtual and augmented reality to bring it to life. This kind of ambitious approach has the potential to change the landscape of safety management in high hazard industries.

For more information, speak with our experts: