A Constructional Data Form, also known as a Component Data Form or CDF, is a list of critical components for a piece of equipment or device. The CDF is a critical tool for ensuring that a machine or product is constructed with the same critical components throughout the entire life cycle of production.

Why Do You Need a CDF?

CDFs assist manufacturers and engineers in keeping track of all the critical components within a machine/product. Inspectors also need a CDF to guarantee that the construction of a product matches the original design.

During a factory audit, the auditor ensures that the certified products built in the factory are using the same components listed in the CDF. It is the manufacturer’s responsibility to ensure that components used in the construction of their products match what is listed on the CDF.

It is also the manufacturer’s responsibility to inform an auditor if there are any changes in components within their product. Failing to do so can potentially result in the termination of their products’ certificates of compliance.

What's In A CDF?

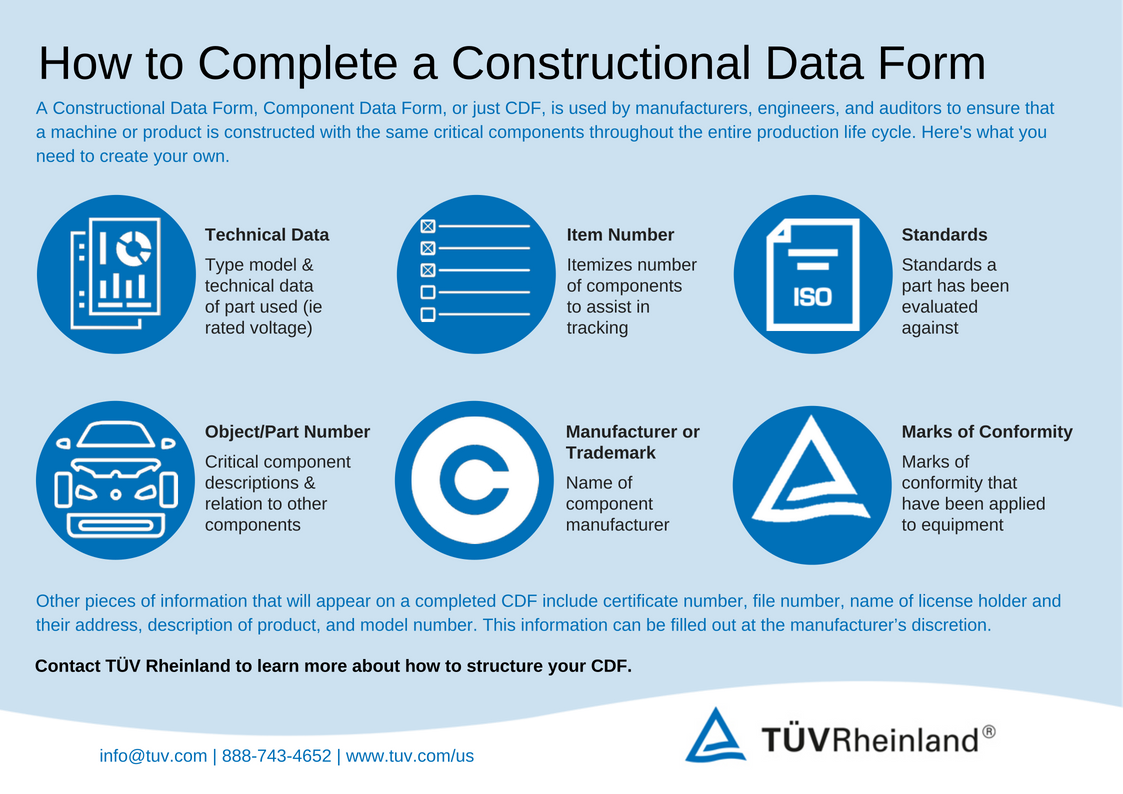

A CDF should list important product information such as components used, technical data of components, type/model of components, and manufacturer/trademark of components.

List of Critical Components:

- Item number – This column is meant to itemise the number of components present in the device. This will assist in tracking the number of components used.

- Object/part number – Fill in all major/critical components of the equipment/device being evaluated. The same designation is required for the identification of the components in the equipment, electrical schematic and CDF.

- For example, a circuit breaker designated with the part no “CB.1”.The object is the circuit breaker and its part no. will be “CB.1”. The designation for this circuit breaker must be reflected on the equipment, electrical schematic and CDF.

- A critical component is defined as a component and/or sub assembly identified during a product evaluation deemed to have an impact on the safe operation or safety features of a product as dictated by the applied standard(s). The component can be electrical, mechanical or structural.

- Manufacturer/ Trademark – Fill in the name of manufacturer of component used.

- Type/Model – Fill in the type designation or model of the component used.

- Technical Data – Fill in the relevant technical data associated with the part used. Examples of technical data typically listed are rated voltage, current, power, frequency and horsepower (for motors).

- Standard – When required by the certification scheme, fill in standards that the component in question has been evaluated against.

- Mark(s) of Conformity – Fill in any marks of conformity that has been applied to the equipment (i.e. UL listed, CSA, TÜV).

Other pieces of information that will appear on a completed CDF include certificate number, file number, name of license holder and their address, description of product, and model number. This information can be filled out at the manufacturer’s discretion.

TÜV Rheinland engineers can help manufacturers demonstrate compliance by assisting in the creation of Constructional Data Forms for all of their products. Contact us to learn more about how to structure your CDF.

For more information, speak with our experts: