Government officials, energy suppliers and investors looking to provide reliable services and profit from strong infrastructure are keen to support quality projects implementing tested and certified components and materials as well as cost-efficient and environmentally-friendly resources. Authorised by the Indian Ministry of New and Renewable Energy (MNRE), TÜV Rheinland India is currently conducting testing of solar pumping systems for use in irrigation and drinking water applications.

Challenges faced by India’s rural pump systems

Because agriculture in India makes up an impressive 16% of GDP and employs a whopping 50% of the workforce, reliable irrigation is of utmost importance to individual farmers as well as the nation. At this time, the country uses approximately 85 million tons of coal and over 4 billion litres of diesel fuel each year to support pumping water for irrigation. In many villages, their agricultural fields and drinking water systems are not connected to the national electricity grid, and those which are often suffer from power shortages, power cuts or load shedding.

To offset these challenges and move toward cheaper and cleaner alternatives, the MNRE has taken steps to promote solar pumping systems powered by the country's year-round supply of rich sunlight. These strategies include statutory compliance to quality standards to ensure solar pumps reliably perform to produce expected levels of water supplies. MNRE has mandated that these systems be tested and certified by recognised, independent laboratories and has selected TÜV Rheinland to act on their behalf as an authorised testing centre.

MNRE chooses TÜV Rheinland India

During initial technical presentations for other projects, TÜV Rheinland emerged as an ideal partner to provide ministry officials the expertise necessary to establish minimal quality and performance standards, develop reliable laboratory testing procedures and issue internationally recognised certification for solar pumps entering the market. After successfully testing sample systems using solar array simulators for the first time in India, TÜV Rheinland India was designated as an MNRE authorised, independent test centre to ensure pump manufacturers and system integrators meet the minimum required discharge per day according to the MNRE guidelines for complete pumping systems.

State-of-the-art solar pump testing setup and procedure using solar array simulation

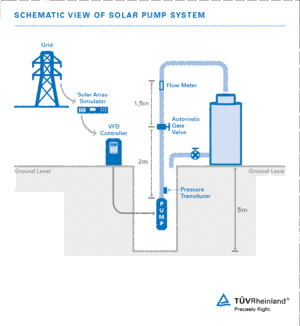

The first private independent laboratory with a fully automated testing setup to evaluate solar pumping systems, TÜV Rheinland India has introduced technical procedures to produce quick and accurate results. Because the method implements a solar array simulator, testing is not dependent on actual sunlight. Testing schedules can therefore be easily followed to ensure timely completion. Since launching the project, TÜV Rheinland India has successfully tested over 1000 solar pumping systems.

Although there are no standardised regulations in place to follow at this time, testing is currently being conducted according to MNRE guidelines which depend on the local requirements and water source availability. Photovoltaic module details are entered into the solar array simulator and conditions are simulated to defined summer and winter irradiance profiles and temperatures provided by the MNRE. Test run time for the hot/summer profile is around 14 hours and 30 minutes, whereas cold/winter profile run time is approximately 12 hours and 45 minutes. The required head/pressure in the water line is controlled by an automatic gatevalve throughout the test sequence and water delivery is measured by an electromagnetic flow meter. Prior to the actual profile run, equipment undergoing testing is subjected to protective tests including examinations of open circuit and output short circuit as well as dry runs.

Results are evaluated by the cumulative measurements captured in the flow meter and the total flow achieved throughout the day. Expert TÜV Rheinland technicians can then precisely calculate and report on the overall efficiency and operational stability of the system.

Because systems in rural areas are very often run by simple farmers or laymen, solar pumps must also be fitted with special accessories such as remote monitoring as well as short circuit, reverse polarity and ingress protections.

Currently testing pumps for the entire Indian market at facilities in Bangalore, TÜV Rheinland is looking to propose minimum quality requirements, develop its own standard and expand solar pump testing services into other regions including Africa, South East Asia and Western China.

Reduced time-to-market and increased competitiveness with successful MNRE registration

Solar pump manufacturers, integrators and distributors are all encouraged to register their products with the MNRE to prove compliance with quality testing by an independent authorised laboratory. As an authorised test centre listed on the ministry website, TÜV Rheinland India provides mandatory testing and issues the appropriate reports and documentation needed for achieving MNRE channel partner registration.

Working as a compulsory local representative, TÜV Rheinland India expeditiously conducts factory inspection and sample testing with lead times ranging from only 3 working days to 8 weeks, based on individual product categories.

Registered channel partners are granted access to participate in ministry tenders and gain an advantage over unregistered competitors in the market. The MNRE involvement and its commitment to quality products and alternative energy sources will attract new manufacturers and system integrators to the solar and renewable industry as well as boost business for the solar sector providing clean, reliable and cost-efficient energy for irrigation and drinking water applications. TÜV Rheinland India will continue providing its support with expert testing, certification and registration services.

The importance of quality standards to positively impact development worldwide

Development banks, governmental agencies and private investors providing funds to rural electrification projects are aware of the potential risks to investment posed by untested pumps. Testing to verify quality requirements offers assurance of minimum performance levels in the field to ensure development projects meet prescribed supply targets in order to protect investment and contribute to a prosperous and healthy populace.

For more information, speak to our experts: