Almost, every person on the planet is in contact with some sort of textile, fabric, or footwear. Each of these products uses chemicals during the manufacturing process – either to achieve a function like water-repellence, for adding texture, or more commonly for color. The wide use of chemicals, the large quantity of water, and the presence of hazardous chemicals in the waste water are some of reasons for the apparel and footwear sector to be regarded as one of the most environmentally polluting industries in the world; along with safety risks for workers and consumers.

This growing awareness and concern of health, safety, and environmental issues related to chemicals in textiles have been driven by numerous factors:

-

an increased knowledge of the hazards associated with chemicals used

-

legislations (such as REACH in the European Union or California Proposition 65 in the USA)

-

campaigns by NGOs like Greenpeace’s Detox campaign

-

the desire of modern consumers for products that are safer for human health and environment.

Commitment of the industry and TÜV Rheinland’s engagement

While efforts by the industry to address the challenges were already underway via OIA’s (Outdoor Industry Association) Chemical Management and Sustainability workgroup; and via SAC’s (Sustainable Apparel Council) Higg Index; this was further enhanced via ZDHC’s (Roadmap towards Zero Discharge of Hazardous Chemicals) efforts.

ZDHC’s mission is to advance towards zero discharge of hazardous chemicals in the textile and footwear supply chain and act to improve the environment and people's well-being. This is to be achieved by widespread implementation of sustainable chemistry and best practices in the textile and footwear industries to protect consumers, workers, and the environment.

TÜV Rheinland supports the ZDHC Programme’s vision and is excited to be joining over 20 leading brands working together to drive industry-wide change in responsible chemicals management, and commits to working on this task in a collaborative and open manner.

“The ZDHC Programme was born from an awareness that holistic systems change was required, and that to be successful, all participants within the value-chain must be involved,” said ZDHC Foundation Executive Director, Frank Michel. “This year, the Programme is shifting its attention from the development of tools towards implementation. Garnering greater industry support and collaboration is essential to driving these ambitious new standards forward.”

“As a globally active service provider, we are confronted by the environmental repercussions of current economic policy on a daily basis. Our experience has shown us the possibilities of environmental protection but has also made us aware of its limits.” said Global Business Field Manager Softlines & Vice President Global Key Accounts, Mr Mohammed Dkhissi.

“The vision of ZDHC of using best practices for protecting consumers, workers, and the environment are fully aligned with our mission of the promotion of greater quality, safety, and economic efficiency where people, technology and the environment interact, symbolized with the triangle in our logo. We aim to employ TÜV Rheinland Group’s knowledge of the impacts of textile & leather production processes and products in a preventative and foresighted manner.” said Program Manager for Textile Sustainability Solutions, Mr Rakesh Vazirani.

Additionally, with our membership in the SAC, TÜV Rheinland joins over 170 global brands, retailers and manufacturers, as well as government, non-profit environmental organizations, and academic institutions, which are collectively committed to improving supply chain sustainability in the apparel and footwear industries. Apart from being a contributing member, TÜV Rheinland’s experts are also involved with Training and Assessment activities related to the Higg Index.

Industry Challenge and TÜV Rheinland’s response

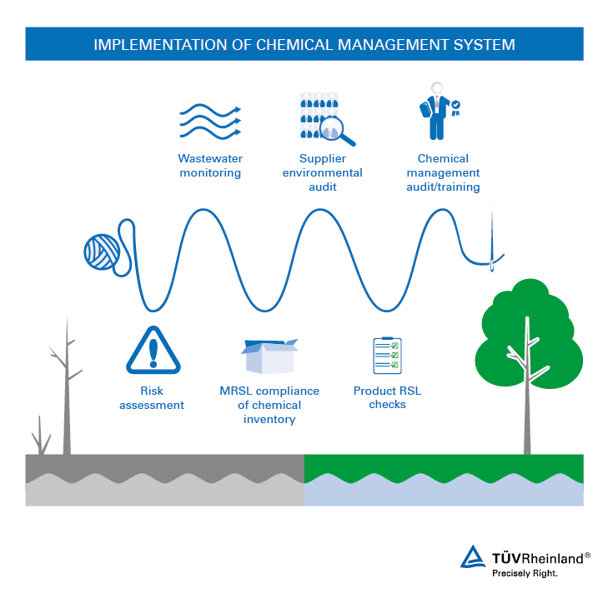

Considering the fact that today’s Fashion supply chain is an intertwined web of chemical suppliers, global commodity farmers, synthetic material developers, mills, and factories; a holistic solution to address the aforementioned challenges would require awareness and capacity development via Technical Training, improvement monitoring via Audits, and conformance via testing at all relevant steps of the supply network.

With our group of experts in the producing countries, we engage in end to end solutions for the apparel and textile industry. As an independent technical Testing, Inspections, Certification provider; our team of experts will be involved at a location near you with status-quo assessment (factory conditions, processes, waste water, and products), monitoring progress, and with capacity development efforts.

Contact us for

-

Trainings about Sound Management of Chemicals, Chemical Inventory Management with our proprietary TOGS database, SDS interpretation, SAC Higg Index assessment.

-

Auditing as per “Sound Management of Chemicals” principles

-

Waste Water Testing

-

MRSL Testing of chemical formulations.

Talk to us at upcoming ZDHC-CNTAC conference in Shanghai on Nov 8.