When it comes to product certification, what kind of value do you expect? This loaded question could certainly be rhetorical. Really, who can say they value a service that many feel is a “necessary evil?” You’d certainly be justified in feeling that way. But I’m going to argue that you really shouldn’t feel any animosity towards your conformity assessment provider if they’re providing you what you need. Further, if new product development is aligned with product certification, there is little chance you will be dissatisfied with your product certification requirements.

Let’s take a closer look at these deliverables and why they’re so important to product manufacturers.

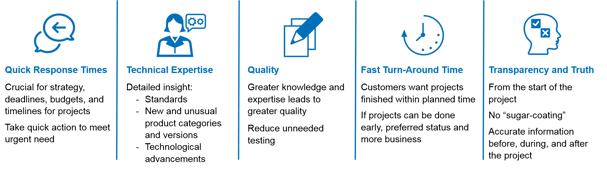

Quick Initial Response Times

When a manufacturer comes to a TIC with a potential project, they are usually up against a deadline to either start a project or to receive a budgetary number to base their own machinery quote on. TICs that are apathetic and unresponsive to initial requests are usually stereotyped problematic and quickly discounted by the prospective customer. Think of it this way: A serious paramedic is someone who quickly responds to an emergency. Believe me when I say, I’d rather be able to call on a serious paramedic if my health was in trouble. Same thing with product certification. I’d rather call on a TIC that I know will respond quickly to my urgent need. I’d even be willing to pay a little more knowing that my life would be well taken care of, right?

Strong Technical Expertise

Customers want a TIC that has the detailed insight to see beyond the areas of the standards that are visible to the naked eye, not just one that has the proper accreditations. Standards are created with a homogenous perspective to encompass new and unusual product categories, reflective of new and improved product versions, technological advancements, or updates. The result of using a TIC with poor technical expertise can be longer lead times for project completions, additional testing that may have been missed, strange interpretations to the standard that might require unnecessary testing, and more.

Quality Evaluations

This is directly affected by technical expertise. If knowledge of the standard is limited, the quality of an evaluation will be jeopardized. Moreover, if a TIC struggles with their technical expertise, chances are their operation is going to struggle. This will lengthen the overall project completion times. Customers expect that technical interpretations of standards will be properly applied the first time and that additional testing will not be needed later. Nothing is worse than to work through a lengthy certification project only to learn additional testing is needed. Regardless of the reasoning, a good quality evaluation will be right the first time, saving time, money, and feelings of frustration.

Fast Project Turn-Around Time

Customers of conformity assessment projects are after one thing and one thing only… certification. Whether that be the listing of a product, a field label, or a CB report, customers want the project finished and according to the agreed upon time frame. If projects can be done early, look out! You’re about to earn preferred status and earn more business. However, if the project timeline slips and communication is poor, a manufacturer will panic. Not just because the timeline is slipping, but due to lack of or incorrect information.

Transparency and Truth

Tell the customer the truth from the start of the project and don't waste time “sugar-coating” anything. Accurate information before, during, and after a certification project is priceless.

A manufacturer is creating strategy around the information you’re providing. If the information is good, the strategy is good. Consequently, if the information is bad, the strategy is bad.

There is nothing more discouraging and upsetting to customers than to formulate production and delivery schedules, only to find out, the information was incorrect. The ensuing domino-effect is chaotic and reactionary - and reaction can be expensive.

Allow me to illustrate from my experience as a Product Manager... I faced a difficult situation that required an immediate decision. A new product scheduled to launch in a month with a major distributor was going to be delayed due to a last minute change to the certification process. This was a serious issue when you consider the distributor represented 40% of the forecasted revenue. The TIC my engineering group was using did not interpret the standard correctly. They delayed in telling us changes they thought were needed. Thus, this extended the certification timeline by an additional two months. Sound familiar? My engineering group brought me the problem and said I could stay with the timeline of the current certification provider, or I could move the project to a competitor who would accept our current test data and provide the certification in three weeks.

What was the difference was between the two certification providers? Nothing. Both were Nationally Recognized Test Laboratories (NRTLs) and accepted by the distributor. It only took two seconds to make my decision to move to the quicker provider and to salvage my revenue forecast. What the initial certification provider failed to realize was their lack of communication had serious consequences.

So, Where is the Value?

One of my favorite value illustrations is what I call the, “You get what you pay for” diagram. In product manufacturing, there are three simple items every customer looks for: quick delivery, great quality, and an amazing price. It is common for a customer to receive only two of the three needed values based on logistics. For example, if you want quick delivery and a quality product, you’re going to pay a higher price. If you want a low price and a quality product, you’re not going to receive it quickly. And if you want it quickly and want to pay a low price, you’re probably not going to get a quality product.

In product certification, it doesn’t work that way. TICs are expected to deliver a quality certification experience at a predefined price in a predetermined time frame. If they are unable to do so, there are options available that can help make life easy. Do a little research and find a solution that will exceed your needs. Or, if you are struggling to know where to start or when time is against you, reach out and I’ll be happy to assist in finding you a solution that can exceed your expectations.

Peter Grundberg

Peter Grundberg is a strategic commercial executive, brand builder, and growth architect for industrial equipment / machinery manufacturers, and product testing / verification laboratories that operate in the Industrial markets of Power Generation, Control & Automation, Renewable Energy, Oil & Gas, Transportation, Mining & Construction, Heavy Industrial, and Hazardous Locations.

For more than 15 years, Peter has been actively involved with product manufacturing and conformity assessment services, expanding business and helping companies manage their risk as it relates to their new product development.

From his early roots in product management to his maturation into global product marketing, category operations, and business development leadership, Mr. Grundberg has created and successfully implemented strategic business plans that have refined operations, built and optimized distribution channels, strengthened supplier / vendor relationships, and generated substantial gains to companies in the areas of brand awareness, product acceptance, revenue growth, and profitability.

As someone who is passionate about helping to effect positive change, Mr. Grundberg enjoys blogging, presenting, and consulting on conformity assessment topics that clients can use towards improving their new product development, manufacturing & distribution facilities, and supply-chain optimization.