By Mr. Bhavin Kachhia, Assistant Manager – Products, TÜV Rheinland India

The Electric Vehicle industry is at a nascent stage in India. At present, Government schemes and subsidies are playing a major role in driving demand and fueling growth in this market. Additionally, increasing environmental concerns, especially regarding high pollution levels in large cities, are changing consumer mind-sets and thereby fueling positive market growth. There are several serious players in this industry today who are collectively trying to bring about a positive change under the banner of the Society of Manufacturers of Electric Vehicles (SMEV).

Benefits of Electric Vehicles and Market Potential:

One of India’s major development goals is the urgent need to reduce carbon emissions, increase energy security, improve fuel economy, and lower fuel costs. The wire and cable industry now has new opportunities to expand, thanks to the rapid development of the EV industry.

According to a recent market research report, the global EV charging cables market is projected to grow at a CAGR of 31.8%, to reach USD 1,808 million by 2027 from an estimated USD 198 million in 2019. Factors such as increasing the adoption of electric vehicles, the rapid development of electric vehicle supply equipment, and increasing demand for fast charging cables would drive this growth.

Why Testing is Important:

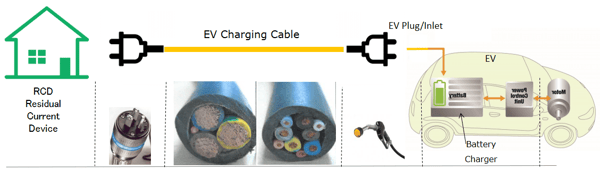

Manufacturers and operators of Electrical Vehicle (EV) charging systems and components i.e EV Charging Cable, Plugs, Socket-Outlet Connectors must maintain high standards in a competitive market. Indeed, a reliable charging system backed up by an internationally recognized certificate of safety and performance is both a key selling point and an essential step in proving compliance.

Reason for compliance – The charging station for electric vehicles (EV) is a complex system comprising an energy management system, smart grid communication, and billing system. Compliance with safety and quality requirements ensures the safety of its usage by the public while minimizing potential financial loss for charging system operators. Compliance with safety requirements helps to export products and thereby expands market access.

Pioneers in Electric Vehicle Testing:

TÜV Rheinland is the Certified Body Testing Laboratory (CBTL) in the Asia-Pacific region and stands out globally as a forerunner and acknowledged leader in EV testing worldwide. With sophisticated laboratory facilities, our global E-Mobility team plays an indispensable role in the sustainable development of the EV industry.

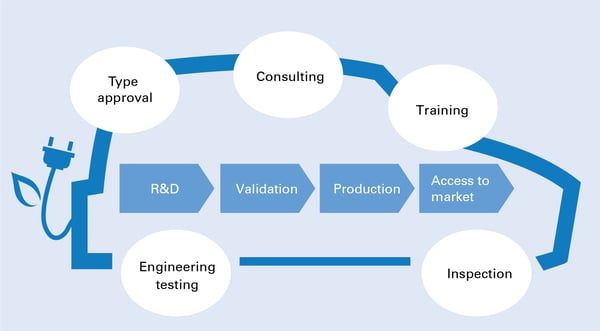

Our services:

TÜV Rheinland provides services and solutions covering the entire EV value chain, including design reviews, engineering testing, type approval, installation, inspection, market access services as well as training and consulting. What’s more, our entire portfolio is available as a one-stop service with a single point of contact.

TÜV Rheinland has been at the vanguard of electric vehicle testing and inspection from the industry’s infancy, and we are still the only company capable of providing services for the entire EV supply chain. Industry leaders trust us with the testing and certification of their products, confident in our ability to demonstrate compliance with the full range of international regulations.

TÜV Rheinland has been at the vanguard of electric vehicle testing and inspection from the industry’s infancy, and we are still the only company capable of providing services for the entire EV supply chain. Industry leaders trust us with the testing and certification of their products, confident in our ability to demonstrate compliance with the full range of international regulations.

Professional testing to facilitate global market access for EV Charging Cable:

With the official release of EV Cable Standard IEC 62893 series, the global EVs and charging facilities industry has rapidly developed. In 2011, TÜV Rheinland became the first technical service provider in India as well as globally to issue an industry-recognized electric car charging cable standard. TÜV Rheinland provides international certification service for EV cables as per EN 50620 and IEC 62893 series standards to help companies seize global market opportunities.

The European Committee for Electrotechnical Standardization has announced standard which is EN 50620:2017. This standard covers electric and charging cables for electric vehicles and there has been a recent amendment which is EN 50620:2017/A1:2019.

This standard specifies design, dimensions and test requirements for halogen-free cables with extruded insulation and sheath having a voltage rating of up to and including 450/750 V for flexible applications under severe conditions to supply power and communication to an electric vehicle.

The Cable may be:

- An integral part of the vehicle; or

- The cable part of a detachable cable assembly with a vehicle connector and AC supply connection to a socket outlet; or

- Permanently attached to a fixed charging point

The sizes of cable can be:

- Power cores 300/500 V – 1.5 mm² and 2.5 mm² - 3 core

- Power cores 450/750 V – 1.5 mm² 3 core and 2.5 mm² to 35 mm² - 3, 4 and 5 core

- Control core/Control Pilot cores– 0.5 mm² to 1.0 mm² - number of cores not specified

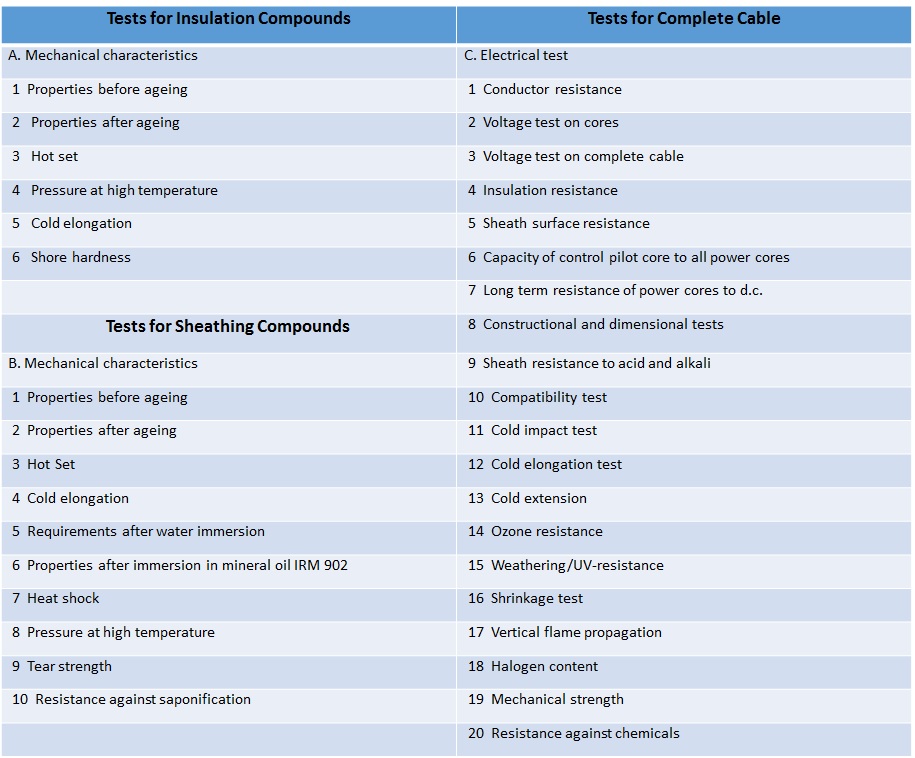

Applicable Tests for EV Charging Cables

Globally recognized testing and certification of cables for various application:

TÜV Rheinland has almost 20 years of experience in testing and certifying wires and cables – with in-depth knowledge of the latest international certification criteria for wire and cable products. We provide a professional, one-stop local service for following cables:

- Cables for PV power systems / Solar cables

- Medium and high voltage cables

- CPR cables for buildings

- Cables for railway applications/ railway rolling stock cables

- Robot and nuclear cables

- Energy storage cables

- Arc-welding cables

- Lift cables

- Wind turbine power cables

- Cables for digital communication

- Optical fiber cables

Conclusion:

Governments across the world are taking initiatives to promote the adoption of electric vehicles. We are seeing significant investments in countries such as China, India, France, and the US to develop a charging infrastructure to support market growth. Governments have introduced various policies to encourage the use of electric vehicles which further drives the growth of this market. A recent market report projected that the Asia Pacific region is estimated to be the largest market for EV charging cables. The governments of China and India have recognized the growth potential of the global electric vehicle supply equipment market and, hence, have adopted several initiatives to attract major OEMs to manufacture electric vehicle charging infrastructure in domestic markets. An increased number of EV charging stations is expected to drive the market for EV charging cables in the region.