A great variety of chemicals is used in the manufacturing of apparel and footwear to facilitate production and to obtain desired properties in the finished product. Consumers are now paying more and more attention to the effects of those chemicals, especially to their impact on human health and the ecosystem.

For you as a manufacturer it is therefore highly advisable to update your knowledge of international regulations and Restricted Substance Lists, RSLs, regularly. You should also aim at raising the awareness of your suppliers to ensure that they understand the importance of following chemical regulations and the requirements of your buyers.

A great variety of chemicals is used in the manufacturing of apparel and footwear to facilitate production and to obtain desired properties in the finished product. Consumers are now paying more and more attention to the effects of those chemicals, especially to their impact on human health and the ecosystem.

For you as a manufacturer it is therefore highly advisable to update your knowledge of international regulations and Restricted Substance Lists, RSLs, regularly. You should also aim at raising the awareness of your suppliers to ensure that they understand the importance of following chemical regulations and the requirements of your buyers.

Some common restricted substances in the manufacturing of apparel and footwear

- Azo dyes are the largest, most versatile group of organic dyestuffs, and are used to dye synthetic and natural fabrics as well as leather. However, the use of azo dyes is problematic as those dyes can break down, releasing one or more aromatic amines in the process. 14 amines, as listed on Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council (REACH Regulation)[1], are classified as Category 1 or 2 carcinogens.

- Pentachlorophenol (PCP) is used as a pesticide, fungicide and product preservative on textiles and leather products, among others. It is classified as a serious health hazard, being acutely toxic and hazardous to the environment. Exposure to high levels of pentachlorophenol can cause increases in body temperature, harm the liver and damage the immune system. Additionally, exposure to PCP is associated with reproductive and developmental effects.[2]

- Formaldehyde is commonly used to make fabrics crease-resistant and waterproof or as an additive in the tanning of leather. It is highly toxic to all animals, regardless of intake. Concentrations as low as 0.1 parts per million (ppm) in the air can irritate the eyes and mucous membranes. Besides, aqueous solutions of formaldehyde are very corrosive. Chronic exposure to higher amounts of formaldehyde has been linked to some types of cancer in humans.[3]

- Organotin compounds are mainly used as stabilizers for PVC, catalysts in the production of PU and as biocides in textiles and leather. Accordingly, they can be found in products made from these materials. Classified as serious health hazards, many substances belonging to this group are acutely toxic and hazardous to the environment. They can act as endocrine disrupters (preventing the body’s hormones from working properly). Acute toxic effects include muscular weakness, breathing problems and severe skin, eye and mucous membrane irritation.[4]

- Nonylphenol and Nonylphenol ethoxylates are usually found in leather, fiber, ink/paint and fabric. There is little evidence for any significant acute effects of exposure to nonylphenol ethoxylates on human health. However, their similarity to estrogen, paired with their low biodegradability and tendency to undergo bioaccumulation cause them to have long-lasting implications for the environment. They cause extensive damage to aquatic life and may negatively influence human development.[5]

Apparel and footwear imported to EU and US markets must comply with the applicable laws and regulations. Furthermore, attention must be paid to the additional demands placed by corporate groups, industry associations or consumer organizations who are keeping an eye on compliance with the law and whose regulations are often more stringent.

1. REACH regulation – EU markets

REACH (Regulation No 1907/2006 of the European Parliament and of the Council) came into force on 1st June 2007 is the European regulation related to Registration, Evaluation, Authorization and Restriction of Chemicals. REACH aims to improve the protection of human health and the environment from the risks that can be posed by chemicals. To this end, it commits companies to identify and manage the risks that can be posed by the chemicals they manufacture or market. REACH also implements measures to strengthen the communication along the supply chain, thus ensuring the provision of clear documentation detailing hazards and instructions for safe use.

For risks that are deemed unmanageable restrictions were put in place. There are three groups of critical substances to be taken into consideration:

- Restricted Substances List (Annex XVII of the REACH Regulation): these substances are limited or prohibited for certain uses.

- List of Substances Subject to Authorization (Annex XIV of the REACH Regulation): the use of these substances requires specific authorization.

- List of Substances of Very High Concern that are candidate to be included in Annex XIV of the REACH Regulation (this list is posted on ECHA’s website). Although there is no limitation or prohibition on these substances, companies using them have to comply with certain obligations.[6]

2. Restricted Substances Lists of industrial associations

One example is the RLS of the American Apparel & Footwear Association (AAFA) published in 2007, currently in its 17th Edition (April 2016). Based on government regulations or laws, the list is reviewed, updated every six months and is free for manufacturers to follow and apply.

Later, in July 2012, the Apparel and Footwear International RSL Management (AFIRM) Group published their own RSL Guidance for suppliers. This RSL comprises detailed information about restricted substances that are commonly used in the production of apparel and footwear as well as the testing requirements and testing methods. Current members of the AFIRM Group include: adidas, ASICS, Bestseller, C&A, Carhartt, Esprit, Gap Inc., Gymboree, H&M, Hugo Boss, J. Crew, Lacoste, Levi Strauss & Co., lululemon, New Balance, NIKE Inc., Pentland, PUMA, PVH, and s.Oliver. Most of these brands are also planning and implementing tools to monitor their production during their supply chain to reach zero discharge of hazardous substances by 2020 as they are members of Detox campaign, initiated by Greenpeace.

3. Restricted Substances List of brands

Under pressure of these developments, many of the bigger brands have invested resources into developing their own particular RSLs, striving to raise their quality standards by reducing consumption of harmful and hazardous chemicals as much as possible. Recent company policies attempt a more holistic approach, by eliminating risks as early as possible, from the product development stage to the manufacturing of the final product. Consequently, suppliers at the root of the supply chain are required to test raw materials according to the given RSLs and submit valid test reports to factories before production.

Conclusion

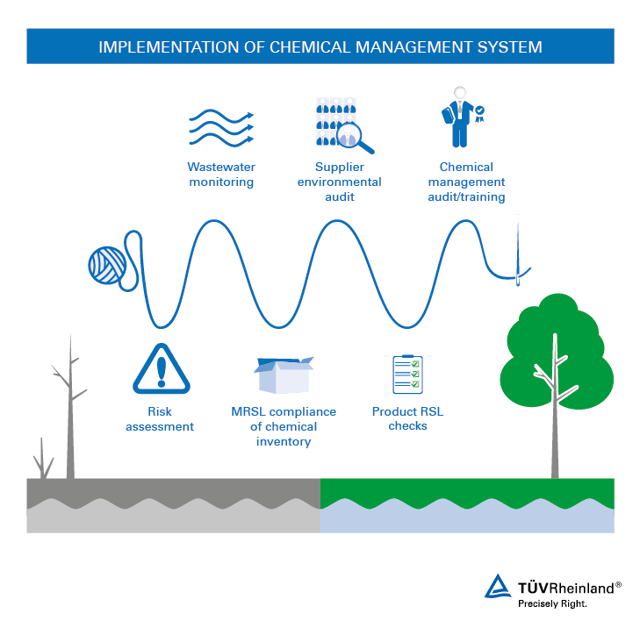

Responsible chemical management is the foundation of delivering sustainable products. Regardless of your place in the supply chain, adhering to compliance guidelines allows you to successfully access target markets, enables collaboration with multinational brands and protects your brand image. TÜV Rheinland is here to help you, offering the best solutions at reasonable cost to ensure you stay ahead of the competition. Please contact us whenever you have any concern about testing requirements of your target markets or your buyers.

[1] http://exporthelp.europa.eu/thdapp/taxes/show2Files.htm?dir=/requirements&reporterId1=EU&file1=ehir_eu13_02v001/eu/main/req_chetext_eu_010_1303.htm&reporterLabel1=EU&reporterId2=NL&file2=&reporterLabel2=Netherlands&label=Restriction+on+the+use+of+certain+

[2] http://www.toxipedia.org/display/toxipedia/Pentachlorophenol

[3] http://www.cancer.org/cancer/cancercauses/othercarcinogens/intheworkplace/formaldehyde

[4] http://garmentstech.com/why-need-to-know-your-socks-underwear-sportswearshoes-leather-products-are-organotins-free/

[5] http://www.toxipedia.org/display/toxipedia/Nonylphenol+and+Nonylphenol+Ethoxylates

[6] Visit https://echa.europa.eu/regulations/reach/ for reference about processes of Registration, Evaluation, Authorization and Restriction of Chemicals according to REACH Regulation

[7] Visit http://ec.europa.eu/consumers/consumers_safety/safety_products/rapex/alerts/main/?event=main.listNotifications for reference about the Rapid Alert System