As more inspectors have turned to CR, the inspection equipment has been steadily improving

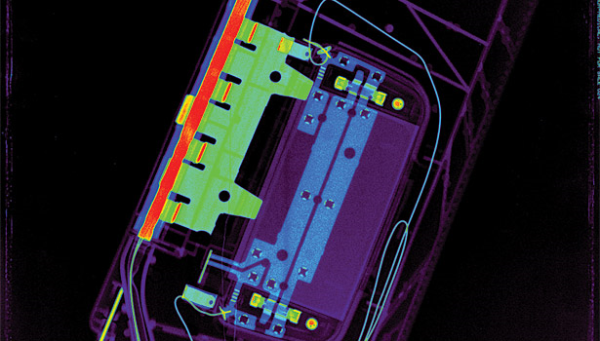

In the NDT world, radiographic examinations are a technician’s staple. Different types answer various inspection and application needs: Computed radiography (CR) is best for aluminum and steel castings, electrical parts, and a wide range of manufactured components. CR can also be used with gamma radiography to inspect very thick-walled steel castings, and has been gaining momentum as digital data storage and retrieval increase in popularity. Environmental concerns over silver recovery efforts and film-developing chemicals as well as increasing film and material prices are all pushing CR forward.

As more inspectors have turned to CR, the inspection equipment has been steadily improving, offering manufacturers faster and more precise and cost-effective NDT results than ever before. The article will discuss the benefits of CR in general as well as describe the functions and benefits of the latest CR equipment available today.

In film radiography, processing requires 10 to 15 minutes and then the film must be checked for density before a technique can be established. In CR, scanning takes about two to four minutes and the image is ready to evaluate—a great improvement in productivity. New CR equipment can scan plates of various sizes, speeding up the processing time. Plates can be made for many different lengths so technicians are not restricted to the traditional film lengths that limit the portion of the component they can shoot at once.

In film radiography, processing requires 10 to 15 minutes and then the film must be checked for density before a technique can be established. In CR, scanning takes about two to four minutes and the image is ready to evaluate—a great improvement in productivity. New CR equipment can scan plates of various sizes, speeding up the processing time. Plates can be made for many different lengths so technicians are not restricted to the traditional film lengths that limit the portion of the component they can shoot at once.

Moreover, CR eliminates the need for film and photo-developing chemicals as CR plates last a long time with respectful handling. That, in turn, reduces the cost of inspection. The digital medium is also friendlier to the environment as no chemicals are employed. In short, the need for film storage is gone, space in the lab is increased, no chemicals are being used, and the impact on the environment is lessened.

For more information about our computed radiography solutions, please visit our website or contact us to speak to one of our experts.