Fashions come and go. But these days, looking good isn’t good enough. Neither is trying to “greenwash” away the environmental impact of a garment or leather product.

Chemical manufacturers play a crucial role in realizing the fashion industry’s sustainability ambitions – making it safer and sustainable with proof of ZDHC (Zero Discharge of Hazardous Chemicals) MRSL (Manufacturing Restricted Substance List) Conformance (Level 1-2-3).

Stakeholders are now demanding independent verification that apparel is manufactured safely in a resource-efficient manner. For an increasing number of brands, buyers, market regulators and environmentally savvy end-user customers, the most important step in that process is demonstrating that the chemicals used during the production process and waste water discharge conform to MRSL requirements.

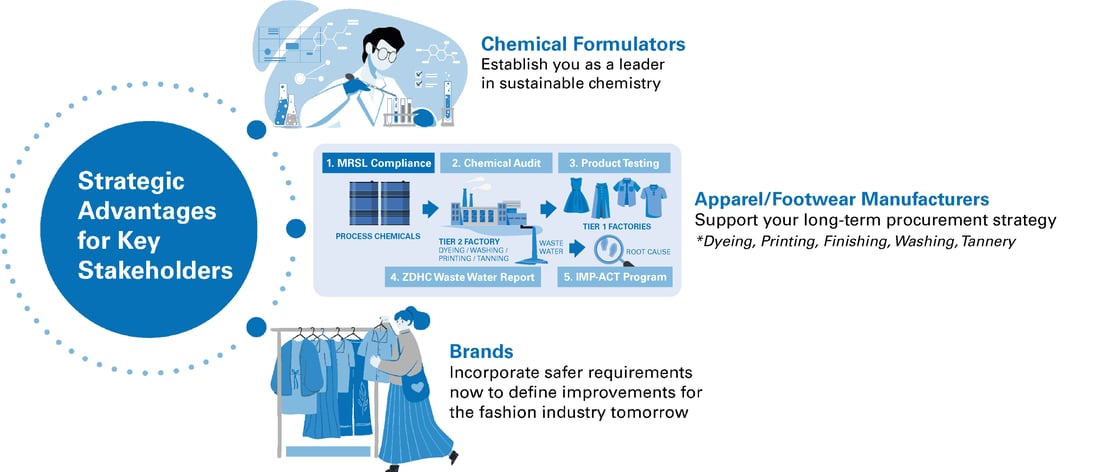

- Chemical Producers

- Provide assurance that chemicals sold in the market are fully MRSL-compliant.

- Eliminate confusion, accelerate sales cycles and increase market demand.

- Brands, Manufacturers & Mills

- Provide proof that the raw materials in the production process are safe-to-use and fully compliant with the relevant standards.

- Create a comprehensive chemical inventory for a totally transparent, trackable and traceable supply chain.

Partnering with TÜV Rheinland offers seamless access to reports you need to achieve a ZDHC ChemCheck report via ZDHC Gateway.

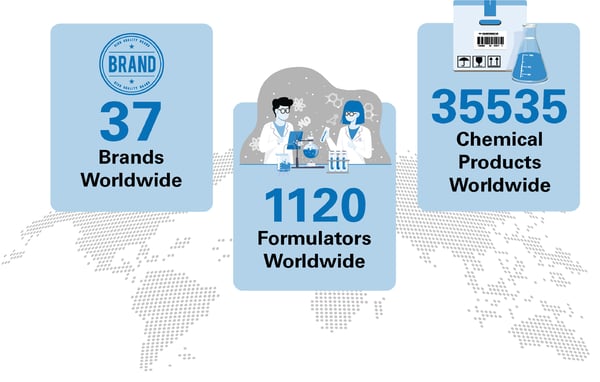

The pace of MRSL adoption is accelerating globally. Thousands of companies have already conformed to MRSL, and many more are working to embrace the ZDHC vision of a safer and more sustainable future for the textiles, apparel and leather industry.

As of July 2021, the number of MRSL-compliant chemical manufacturers included more than 1,000 chemical companies producing over 35,000 individual chemical products.

MRSL cuts out complexity and costs, and increases chemical management convenience across the board.

Factories and other stakeholders can quickly cross-check supplier claims against the certified ZDHC Gateway Chemical Module information, to confirm that a chemical conforms to safety standards, or reject it and search for a safer alternative. The result is a precise understanding and tight management of all chemical inputs.

A critical component of the ZDHC’s “Roadmap to Zero” initiative, MRSL (Manufacturing Restricted Substances) is a chemical management game changer.

Unlike outdated approaches like PRSL (Product Restricted Substances List) restrictions which only apply to finished products, MRSL conformance starts right at the beginning with procurement. Hazardous substances are identified and eliminated from the manufacturing process before they have a chance to cause problems downstream.

Reaping Long Term Green Benefits

- Advantages for Suppliers / Textile Mills

MRSL conformance makes achieving the highest score in any chemical management audit significantly easier – whether it is Higg Index, amfori BEPI or GOTS. Certainty about the chemicals used helps to prevent any problematic substances from entering the facility at source, thus reducing the need to treat and clean-up effluent water downstream.

Covering every chemical formulation in use within the walls of a manufacturing facility – including those used to clean the premises and production equipment – a MRSL-friendly approach protects both the workers inside the plant and the environment outside.

- Advantages for Brands

MRSL conformance also assures brands, regulators and retail customers alike that key chemicals used in the production process is safe and sustainable. The result is a massive “green win” for companies and our planet.

- Advantages for Chemical Formulators

Lastly, MRSL conformance allows chemical formulators to demonstrate their efforts to develop greener and cleaner chemistry at source, which ultimately enhances sustainability for the entire fashion industry.

One-stop Solution for MRSL Conformance Services

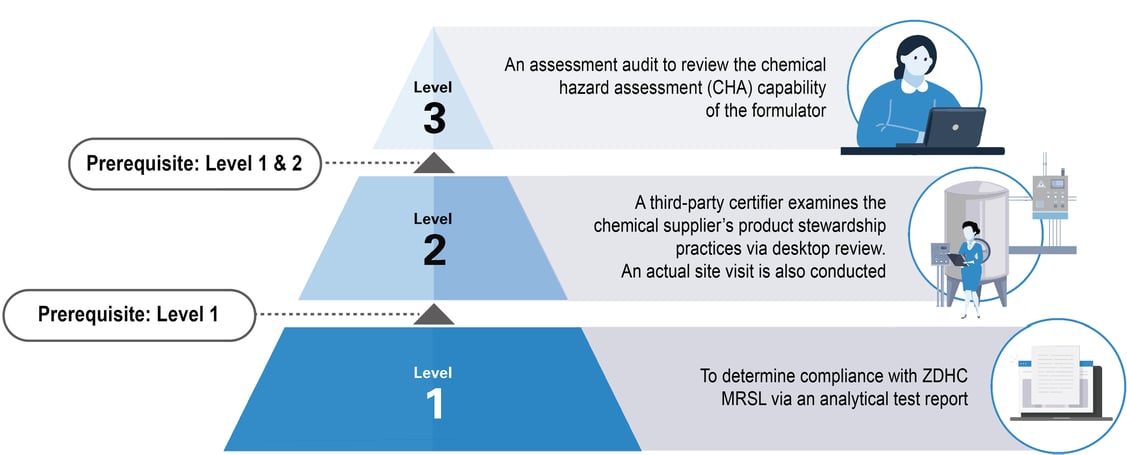

Proving each of the 3 levels of MRSL-compliance calls for the credibility that only an independent testing and certification partner such as TÜV Rheinland can deliver.

TÜV Rheinland is one of the few ZDHC-accredited chemical management solution providers capable of providing the full range of Level 1, Level 2 and Level 3 testing/assessment for the latest ZDHC MRSL standards.

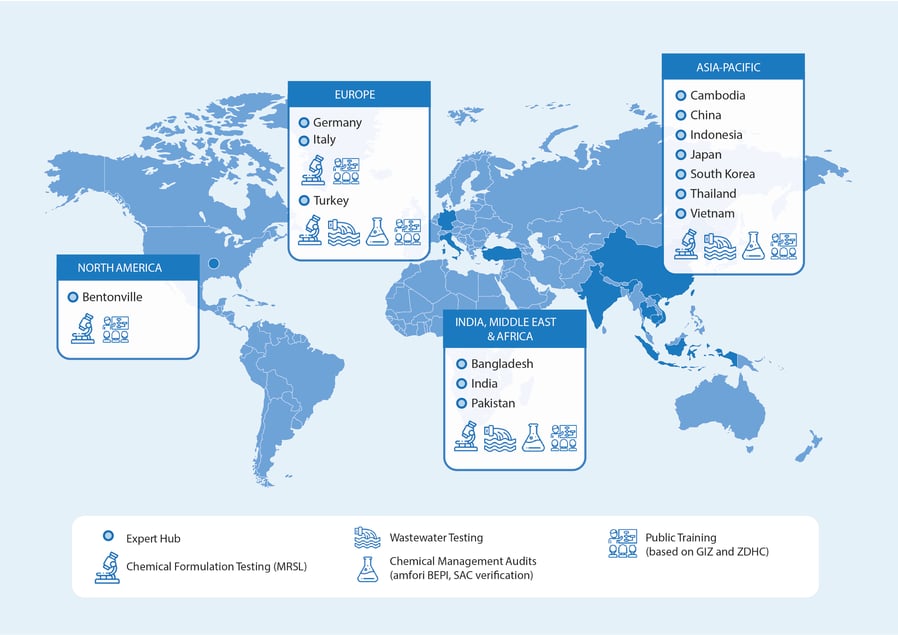

Local Expertise with Global Reach

Our MRSL program is delivered via an extensive global testing and certification network, staffed by internationally-recognized experts and professionals with decades of industry experience.

The network includes APAC locations such as Greater China, Thailand and Vietnam, along with labs in Bangladesh, India, Turkey and Germany. This complements our extensive portfolio of MRSL 2.0 testing and certification services, which are already in high demand.

Specifically, TÜV Rheinland is recognized as the official ZDHC certifier for ZDHC MRSL V2.0 - Level 1, 2 and 3 at the following locations:

- Bangladesh (Contact us)

- China (Contact us)

- India (Contact us)

- Thailand (Contact us)

- Vietnam (Contact us)

- Germany (Contact us)

- Turkey (Contact us)

Additional Detox Service: REACH SVHC

Testimonials

Cosmo Kimya

Initially the ZDHC MRSL process was very difficult for us. After reviewing all the documents and guidelines, it became clear that we needed an experienced third-party laboratory. We considered three candidates before finally selecting TÜV Rheinland who have display strong technical capabilities.

We wanted to work with someone who understand our needs and is able to patiently guide us in solving our problems. Mr. Ata (Area Sales Manager & Textile Industry expert - Turkey) and his team tirelessly clarified all our queries and that really enabled a smooth verification process.

Mr. Kus Nazli, Cosmo Kimya

Production Manager

Turkey

*********

Kimteks Kimya

At Kimteks Kimya, we are proud to have contributed to the fashion industry’s efforts towards achieving DETOX goals through our own progress in ZDHC MRSL conformance. TÜV Rheinland’s expertise is especially crucial in helping our Product Safety team to achieve this goal!

Mr. Aydin Cuneyt, Kimteks Kimya

CEO

Turkey

*********

Samjin

ZDHC MRSL levels achieved: 1

Number of Chemicals Tested: 77

We are fortunate to be introduced to TÜV Rheinland via our customers. With the strong support from the team, we manage to achieve conformance to ZDHC MRSL within a relatively short amount of time. Apart from useful advice on the necessary actions required, the team was quick to relay our clarifications to ZDHC directly for prompt resolution. We really want to thank the TÜV Rheinland’s team for their patience in partnering with us to achieve conformance success!

Mr. Nguyen Huu Tuan, Samjin International

Production Engineer

Vietnam

*********

Sintan Kimya

At Sintan Kimya, we are proud of fulfilling our responsibility towards the environment with the awareness of minimizing our share of consumption for a livable nature. We want to express our special thanks to TÜV RHEINLAND for their continuous support for their technical competence and helpful support in our ZDHC MRSL V2.0 compatibility assessment.

Dr Yilmaz Serpil

PhD Chemist / Business Development and Project Manager

Turkey

*********

Rudra Chemicals

ZDHC MRSL levels achieved: 1

We take immense pleasure to share that we’ve made the right choice in selecting TÜV Rheinland as our testing partner for our ZDHC requirements. During the entire journey, we received all the required support including sample pick, answers to our queries by the technical team and much more.

TÜV Rheinland have also went the extra mile to help us in achieving our goal to be listed on the ZDHC platform. Special thanks to Mr Dilip Padani @ TUV Rheinland (Mumbai) for his patience with us throughout the process. We value all your visits and follow-ups to let us understand the importance of being a ZDHC-compliant unit – which goes a long way to help us achieve our financial goals.

Mr Patel Keyur

Manager

India

*********

KAAN Endustri Muhenislik

We would like to express our gratitude to the very experienced team at TÜV Rheinland who have contributed towards our success on the ZDHC platform.

Mr Guven Alphan

Director

Turkey