The Vietnamese electronics market has grown in leaps and bounds in recent years, but for a long time, bringing a product to market has been challenging due to lack of domestic electromagnetic compatibility (EMC) testing facilities within Vietnam.

For companies in Vietnam that produce and export electronics, the lack of such facilities usually result in a long wait for test result as the test sample has to be shipped to a testing centre outside Vietnam.

With the set-up of suitable testing facilities in Vietnam, more companies are having their products to be subject to EMC testing within Vietnam in recent years. Apart from saving, with shipping costs, this arrangement allows their products to gain quicker access to the global market due to the shorter lead time required to obtain test results. Further, they will benefit tremendously from direct communication with locally-based as well as international experts.

Multinationals choose to test locally

The Japanese-owned multinational Panasonic is among those who have brought EMC testing to Vietnam. Panasonic holds itself to high standards for quality control, requiring that several types of products are subject to annual EMC tests in its diverse Vietnamese portfolio. They include a wide range of electronic products from scanners, business phone exchanges (PBX) to home intercoms.

“Most of our products are related to electromagnetic fields, so EMC testing is a mandatory requirement for our products before and after they go to market.” said Mr. Nguyen The Anh, Senior Manager of the Plant Engineering Department at Panasonic Vietnam. “We have to make sure our products comply with the specific standards and regulations in the country of destination.

Additionally, it’s faster to test the products directly in Vietnam. “Sending products back to Japan took more than 10 days,” Mr. Nguyen The Anh said. “While testing in Vietnam requires just a few days.” The products Panasonic tests in Vietnam go on to be sold in Europe, South America, Japan, and Southeast Asia, where they are known for excellent quality and reliability.

In fact, much of the Vietnamese electronics market’s remarkable growth in the past few years has been due to the export market, which has expanded dramatically from USD $22.9 billion in 2012 to more than USD $71 billion in 2017. Most major investors are large foreign companies which export electronic products globally.

Japan-based Fuji Xerox, the Asia-Pacific region’s pre-eminent producer of print and copy machines, currently manufactures seven types of printers in Hai Phong, Vietnam. The 56-year-old company prides itself on its reputation for well-constructed and durable devices, for which reliable electromagnetic compatibility performance is key.

To maintain that reputation, Fuji Xerox tests and re-tests its products in Vietnam every six months. Ms. Nguyen Thi Hue, Section Leader of Customer Focus and Product Safety, Management Quality Department at Fuji Xerox, highlighted that, “Continually testing for electromagnetic interference allows our products to achieve a high standard of quality and hit the targets that the Fuji Xerox Corporation has set up.”

High quality testing without the hassle

In 2016, TÜV Rheinland, an international testing and certification service provider, opened its EMC testing facility in Hung Yen Province, Vietnam, bringing fast and cost-effective EMC testing to Vietnam.

Since TÜV Rheinland’s pioneering entry, many companies that produce electrical devices in Vietnam are now conducting their EMC tests within Vietnam on regular basis. Both Panasonic and Fuji Xerox rely on TÜV Rheinland to test their products.

Panasonic continually turns to TÜV Rheinland for its “high quality management system, modern equipment, measurement skills, and professional style,” according to Mr. Nguyen The Anh.

The ISO 17025 accredited, 1,000-square-meter lab in Hung Yen Province is the largest and most advanced in the North of Vietnam. It offers a complete range of services for electrical devices, including IT equipment, household appliances, laboratory equipment, sensitive industrial and medical devices, and radio-based devices with Wi-Fi or Bluetooth functions.

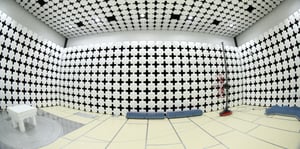

The facility features a 10-meter semi-anechoic chamber with special material on the walls to absorb reflections from electromagnetic waves and isolate the equipment to allow a precise evaluation. It has the capacity to test both radiated (over-air) and conducted (over-wire) emissions, as well as interference susceptibility, electromagnetic pulse immunity, and power surge resilience.

With TÜV Rheinland Vietnam, manufacturers can now test their products in one single location for three key phases: development, prototyping and production stages. Thanks to its proximity and full-service support, this level of thoroughness has now become feasible.

“Fuji Xerox previously opted for a service provider in Korea,” shared Ms. Nguyen Thi Hue. “However, ever since TÜV Rheinland’s facility was established in Vietnam, Fuji Xerox has chosen them as a provider of electromagnetic interference services as we are confident of its high standards, quality equipment and services offered during the EMC testing process.”