Wind turbines, power plants, high-temperature energy systems, storage devices and the like are exposed to enormous stress on a day-to-day basis. Damage to this type of equipment not only causes potential production failure and enormous repair costs but also a loss of reputation. While up until a few years ago this kind of plant had to be shut down to enable repair work to be carried out, today companies make use of so-called condition monitoring systems. These allow damage to machines and equipment to be identified early on so that they can be shut down promptly for maintenance work to be carried out selectively.

Condition monitoring system application in gas caverns

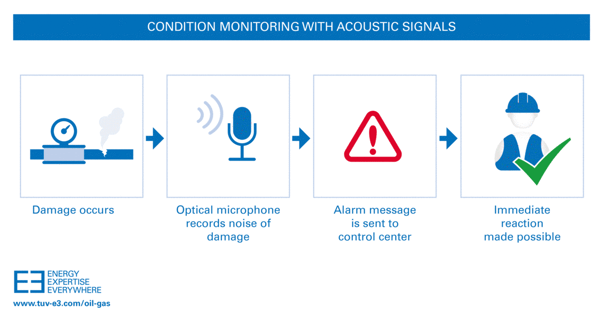

The basic concept was showcased at the EXPO in 2000 under the name HISS - “Human Interface Supervision System.” The groundbreaking idea at the time was that a computer with “sensory” organs would identify leaks and damage to the machinery directly and pass this information on. Since then, condition monitoring systems have been used to monitor various types of technical plants and machines during operation. Special microphones or sensors are the helpers of the future: they register acoustic signals or vibrations directly on the spot and relay any irregularities to the control center. In this way, acute anomalies can be captured promptly and eliminated, thereby ultimately reducing follow-up costs. There are a wide range of potential uses, with gas caverns requiring special attention. These special reservoirs are located in natural or man-made cavities underneath the earth’s surface and serve to compensate any imbalance between availability and demand as well as increasing supply security. Gas caverns are generally filled with gas during the summer months when the demand for gas is low and emptied during the winter months to cover additional requirements.

“Seam runners regularly monitor the gas caverns, but the technical acoustic condition monitoring system ta-COMOS is now used to an increasing extent,” explains David König, industrial and mechanical engineering specialist with TÜV Rheinland. The system draws on its capacity to “listen,” using optical microphones for sound and light wave conversion. This type of optical microphone is required for use in areas at risk of explosion (Ex).

Technical acoustics in 5 steps

1. Optical microphones in the Ex category are used to monitor the condition of gas caverns.

2. They are typically mounted at collection points on the cavern head.

3. The microphone continuously records all noises in its environment. Any leakage near the cavern head causes a high-frequency hiss which is not necessarily perceptible to the human ear.

4. If a sound event occurs within the relevant monitoring area, a message is sent to the control center. The event report is delivered by the computer voice “Steffi.”

5. It is possible to respond immediately to damage, thereby minimizing loss and risks.

Early damage detection saves costs

The investment is especially worthwhile for companies operating in the field of gas storage. “Leakage at the cavern head can result in the rapid loss of a quantity of gas that would normally be used by one or two normal households in a year,” says König. The earlier the damage is detected, the lower the subsequent costs and the less probable it is that the security of the system will be impaired during operation. Condition monitoring is not generally required but is increasingly used by companies of their own accord for security and cost reasons. “In future, monitoring will not be applied to each individual unit, but whole areas will be covered by several devices,” says David König, looking ahead to the future of condition monitoring systems.

Spot vibration measurement and analyses

At a generic level and depending on the area of application, cyclical data analysis based on vibration diagnosis can replace a stationary system. This can also be used with existing monitoring systems (applicable to all manufacturers).

Find out more about our services for the oil and gas industry, or contact us to speak to one of our experts.