By Mr Bhavin Kachhia, Assistant Manager – Products, TÜV Rheinland India

The growth of infrastructure generates scope for further development of the wires and cables industry in India. The wires and cables market in India comprises of nearly 40 per cent of the electrical industry and is growing at a CAGR of 15 per cent as a result of growth in the power and infrastructure segments. According to a recent market research report, the global market is projected to expand at a CAGR of 4.1% during the forecasted period to reach US$ 235.9 Billion by 2026.

In 2011, TÜV Rheinland became the first technical service provider in India as well as globally to issue an industry-recognized electric car charging cable standard.

Factors such as growing market potential, an increased adaption of new technologies by the utilities, and the growing importance of services linked to digital technologies have generated further scope for the growth of wires and cables industry in India.

The wire and cable industry now has new opportunities to expand, thanks to the rapid development of the energy, railway, rail transit, construction, communication, shipping, and automobile industries. To stand out from your competitors in today’s increasingly competitive international marketplace, it is crucial that you demonstrate the quality and safety of your wire and cable products by ensuring compliance with all relevant standards in target markets.

The wire and cable industry now has new opportunities to expand, thanks to the rapid development of the energy, railway, rail transit, construction, communication, shipping, and automobile industries. To stand out from your competitors in today’s increasingly competitive international marketplace, it is crucial that you demonstrate the quality and safety of your wire and cable products by ensuring compliance with all relevant standards in target markets.

TÜV Rheinland has over 20 years of experience in testing and certifying wires and cables – with in-depth knowledge of the latest international certification criteria for wire and cable products. TÜV Rheinland provides you with a professional, one-stop local service for most types of conventional cables, photovoltaic (PV) cables, wind energy-related cables, locomotive cables, high-voltage cables, and many other types of cables.

In 2011, TÜV Rheinland became the first technical service provider to issue an industry-recognized electric car charging cable standard. The standard helped companies gain access to the booming electric car industry.

Our Services:

TÜV Rheinland offers testing and certification based on the requirements of CE, CB scheme, INMETRO, cTUVus, PSE, and S+ with only one set of samples required. TÜV Rheinland enables customers to add value to the products by testing and certifying them in accordance with national criteria, such as GB, DIN, VDE, HD, EN, IEC, BSI, UL, JIS, and AS/NZS norms. Additionally, the tests reports are produced in accordance with specific requirements.

Construction Products Regulation (CPR):

The Construction Products Regulation (CPR) lays down harmonized rules for the marketing of construction products in the European Union (EU) and is getting more and more attention and awareness in the cabling market as the date for obligatory CE marking of cables for use in construction works gets closer. The regulation provides a common technical language to assess the performance of construction products. It ensures reliable information is available to professionals, public authorities, and consumers, so they can compare the performance of products from different manufacturers in different countries.

The basic reference standard for cables and their performance with respect to fire under the CPR is:

EN 50575:2014 (incl. A1:2016) is the basic standard applied for cables used in construction. The standard specifies the reaction to fire performance requirements, test and assessment methods for electric cables used for the supply of electricity and for control and communication purposes, which are intended to use in construction work and subject to performance requirements on reaction to fire.

- Cables covered by this standard are intended to be used for the supply of electricity and communications in buildings and other civil engineering works with the objective of limiting the generation and spread of fire and smoke.

Cables intended to be used for the supply of electricity, communication, and fire detection and alarm in buildings and other civil engineering works where it is essential to assure the continuity of power and/or signal supply of safety installations.

Cables covered in the CPR Scope:

- Power cables: These insulated conductors and cables are used in the supply of electricity

- Control and Communication cables: Wires, symmetric cables, and coaxial cables with metallic conductors are used in telecommunication, data transmission, radio frequency, video communication and signalling and control equipment

- Optical fibre cables: These cables are used in telecommunication, data transmission, radio frequency, video communication, signalling and control equipment

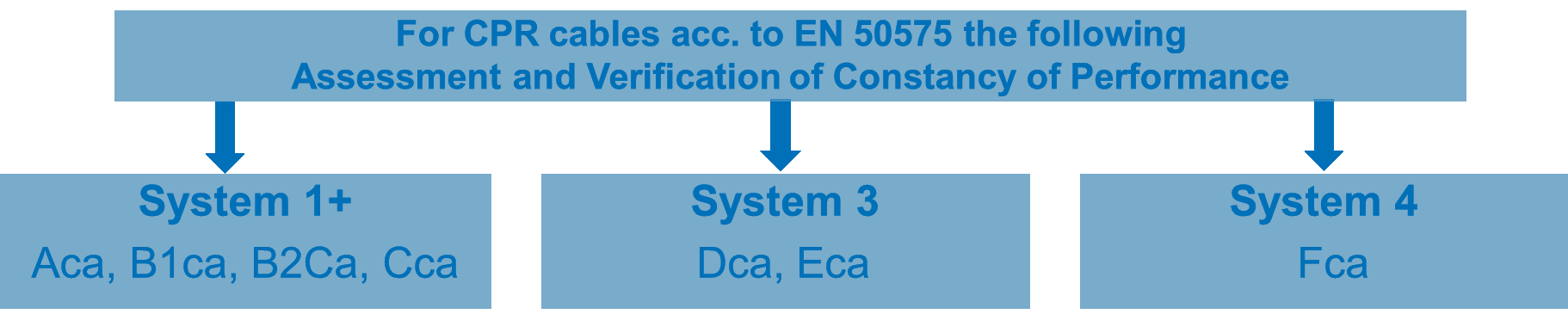

For reactance to fire classes Aca, B1ca, B2ca, Cca, the AVCP system 1+ shall be applied, and the involvement of a Notified Product Certification Body is required. The task of TÜV Rheinland includes type testing, initial –and continuous – inspection and evaluation of the FPC, as well as audit testing of samples. The manufacturer, on the other hand, is responsible for establishing and maintaining the FPC, and for testing at the plant in accordance with the prescribed test plan.

For reactance to fire classes Dca, Eca, the AVCP system 3 shall be applied, and the involvement of a Notified Testing Laboratory is required for the initial type testing. The manufacturer is responsible for the FPC as for system 1+, but with no explicit requirement for testing plans and sample testing at the plant.

For reactance to fire classes Fca, the AVCP system 4 shall be applied. Although no reaction to fire performance is declared for this class, the manufacturer still has to ensure that other requirements in the standard are met (FPC, the release of dangerous substances). The manufacturers may carry out the necessary type testing and assessment themselves, and as for the other systems, the manufacturers are responsible for the FPC.

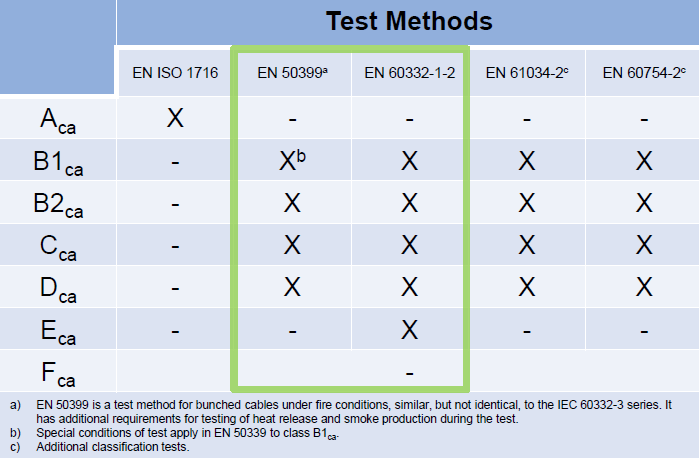

EN 50575 defines the test methods for reaction to fire classes, which also gives guidance on which classes they can obtain for their cable:

- Class A ensures the highest performance (reaction to fire) and Class F is having the lowest

- For reaction to fire testing, the mandatory tests are EN 50399 & EN 60332-1-2

- Additional testing can be applied according to EN 61034-2 & EN 60754-2 based on client request

Product scope:

TÜV Rheinland offers testing and certification services for the following products and product groups:

Electric vehicle cables

o Medium and high-voltage power cables

o Polyvinyl chloride or cross-linked insulated cables

o Halogen free thermoplastic compounds insulated cables

o Cables for hoists and travelling cranes

o Railway rolling stock power and control cables

o Cables for shipboard and offshore applications

o Cables for wind power systems

PV/Solar cables

CPR (Construction Products Regulation)

o Cables for use in power stations

o Cables for digital communication

o Coaxial cables

Optical fiber cables

TÜV Rheinland is a reliable partner:

Test reports issued by TÜV Rheinland are widely recognised by overseas buyers, providing our Indian customers with greater access to global markets. Our internationally recognised test marks demonstrate our customer’s compliance with legal requirements. TÜV Rheinland helps to reduce the risk of liability by demonstrating the safety of the products. Certipedia, TÜV Rheinland’s online certification database, enhances the credibility and competence of players in the wire and cable industry, in both the global and domestic marketplaces.